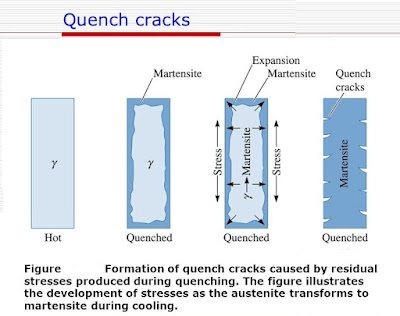

Surface of component, during quenching, cools rapidly and centre cools slowly; therefore phase appearing at the surface and centre are likely to be different. This results in non-uniform volume changes. The overall effect of non-uniform cooling and non-uniform volume changes is to cause heavy distortion and cracking of the components. The cracking may result during quenching or sometimes after quenching, if tempering is delayed or in the easily stages of tempering.

Quenching cracks are liable to occur due to following reasons:

- Over heating: During the austenizing portion of heat treatment cycle can coarsen normally fine grained steels. Coarse grained steels increase hardening depth and are more prone to quench cracking than fine grain steels. Avoid over heating and overly long dwell times while austenizing.

- Improper selection of steel.

- Time delay between hardening and tempering operations.

- Improper design: Sharp changes of section, lack of radii, design of keyways, holes, mass-distribution, and non-uniform sections.

- Improper quenchant or medium: Water, brine or caustic will get the steel "harder". If the steel is an oil hardening steel, the use of these overly aggressive quenchants will lead to cracking.

- Excessive amount of non-metallic inclusions in steel.

No comments:

Post a Comment