DEFORMATION:

The change in dimensions or forms of matter under the action of applied forces is called deformation. It is caused either by the mechanical action of external forces or by various physical and physio-chemical processes. Normally all materials undergo some deformation in their daily use by the application of external load. We are mainly concerned with this type of deformation. A deformation can be classified as either : (i) recoverable or elastic after the removal of external force or applied load; such a deformation is termed as temporary elastic deformation, (ii) non-recoverable or plastic or visco-elastic deformation, this deformation remains even after the removal of the deforming force and applied load; this type of deformation is termed as permanent deformation. Both types of these deformations may be either independent or dependent on time. Metals exhibit less elastic but more plastic deformation even at room temperature while steady flow is predominant at higher temperature ranges. To form various metallic shapes the deformation of metals in necessary.

Types of metal deformation:

The metal deformations are of the following two types:

1. Elastic deformation and

2. Plastic deformation.

(1) Elastic deformation:

Elastic deformation is the deformation which disappears when the load is removed. It precedes (takes place before) plastic deformation. This deformation occurs when a stress is applied on a metal piece. Such type of behavior is common to metals, ceramics, rubbers and polymers.

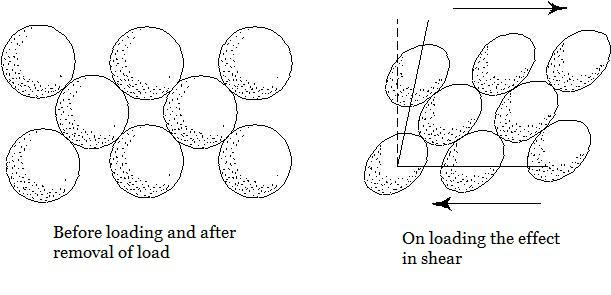

Below Fig shows the form of the atoms before loading, after loading, in tension and compression respectively. When tensile load is applied, the piece before slightly longer and in compression it becomes slightly shorter. On removal of these loads it regain it's original dimensions.

Such deformation in a solid materials obey Hooke's law. For elastic deformation, the strain is nearly proportional to stress. The ratio between stress and strain under deformation is called modulus of elasticity or young's modulus (E).

Shear stress is also set up in crystal structure in engineering applications. These produce displacement of one plane of atoms relative to the adjacent plane of atoms. Obviously, shear stress tends to slide each layer of atoms past the next. The elastic strain is defined as the tangent of the tangent of the shear angle. Up to the limit of elastic displacement the shear strain is proportional to the shear stress. The ratio between shear stress and shear strain is known as shear modulus of rigidity (G).

There are many materials, where Hooke's law doesn't hold good for engineering applications where deformation is large, i.e., for these materials, stress & strain, relationship is no longer applicable. Non-ferrous metals, mild steel, etc., are few examples which show deviation from perfect elastic behavior.

(2) Plastic deformation:

It is the deformation which persists even after the load is removed. For most metallic materials, elastic deformation persists only to strains of about 0.005. As the materials is deformed beyond this point. Hooke's law ceases to be valid, i.e., stress is no longer proportional to strain and plastic deformation is observed. Plastic deformation is typically a function of stress, temperature, and the rate of straining. Plastic deformation associated with the displacement of the atoms within the grains and causes ultimately permanent changes in shape of the material. Tensile, compressive stresses can cause plastic deformation.

In metals the plastic deformation generally takes place by the process of "slipping". The ability of metals to undergo plastic deformation is called ductility.

COMPARISION BETWEEN PLASTIC AND ELASTIC DEFORMATION

S.NO

|

Elastic deformation

|

Plastic deformation

|

1

|

It appears and disappears with the

application and removal of

stress-temporary deformation.

|

It exists even after the removal of

stress-permanent deformation.

|

2

|

It is the beginning of the progress

of deformation.

|

It takes place after the elastic

deformation has stopped.

|

3

|

In elastic deformation, the strain

reaches its maximum value after the

stress has reached its maximum value.

|

In plastic deformation, the strain

occurs simultaneously with the

application of stress.

|

4

|

It takes place over a short range of

stress-strain curve.

|

It takes place over a wide range

of stress-strain curve.

|

No comments:

Post a Comment